Underfloor Heating System

RIFENG’s Underfloor Heating System highlights the use of oxygen-proof PEX pipes, fittings, and manifolds in both residential and commercial projects. We make sure that every single component in our underfloor heating system is designed and produced to the same uncompromising standards.

RIFENG’s Underfloor Heating System highlights the use of oxygen-proof PEX pipes, fittings, and manifolds in both residential and commercial projects. We make sure that every single component in our underfloor heating system is designed and produced to the same uncompromising standards.

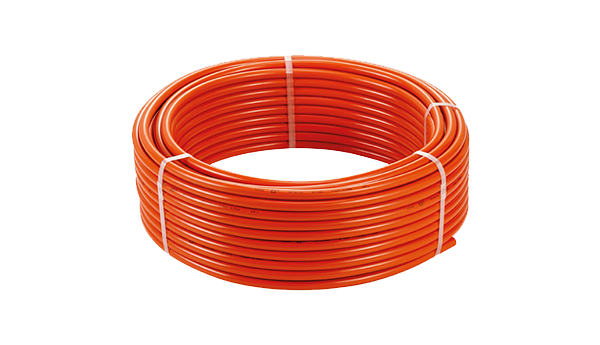

RIFENG Oxygen-barrier PEX Tubing

? RIFENG Oxygen Barrier PEX Tubing is a cross-linked polyethylene tubing with an added oxygen diffusion layer that is suitable for use with most radiant heating and snowmelt systems.

? RIFENG Oxygen Barrier PEX tubing provides superior chemical and mechanical performance, extending the system's lifespan.

? RIFENG Oxygen Barrier PEX Tubing is a cross-linked polyethylene tubing with an added oxygen diffusion layer that is suitable for use with most radiant heating and snowmelt systems.

? RIFENG Oxygen Barrier PEX tubing provides superior chemical and mechanical performance, extending the system's lifespan.

Technical specification

Advantages:

? Pipes resistant to harmful chemicals and meets the CL5 classification of chlorine resistance

? Pipes prevents oxygen permeation through the tubing wall which causes the corrosion of ferrous metal components in closed-loop heating systems

? Pipes is flexible and available in long coils that need less fittings than rigid tube and light in weight

? Manifolds selects material of stable chemical elements and undergoes testing for tensile strength, hardness, and anti-corrosion

? System service life up to 25 years

Applications:

Radiant underfloor heating system

?

? Pipes resistant to harmful chemicals and meets the CL5 classification of chlorine resistance

? Pipes prevents oxygen permeation through the tubing wall which causes the corrosion of ferrous metal components in closed-loop heating systems

? Pipes is flexible and available in long coils that need less fittings than rigid tube and light in weight

? Manifolds selects material of stable chemical elements and undergoes testing for tensile strength, hardness, and anti-corrosion

? System service life up to 25 years

Applications:

Radiant underfloor heating system

?

Standards:

ISO 15875?- PLASTICS PIPING SYSTEMS FOR HOT AND COLD WATER INSTALLATIONS - CROSSLINKED POLYETHYLENE (PE-X)

ASTM F876?- Standard Specification for Crosslinked Polyethylene (PEX) Tubing

ASTM F877?- Standard Specification for Crosslinked Polyethylene (PEX) Hot- and Cold-Water Distribution Systems

WRAS regulations?- WRAS water supply regulations

Certificates:

NSF - refers to ASTM F876/877

WRAS- refers to regulations

ISO 9001:2015 – “Quality management system”

ISO 15875?- PLASTICS PIPING SYSTEMS FOR HOT AND COLD WATER INSTALLATIONS - CROSSLINKED POLYETHYLENE (PE-X)

ASTM F876?- Standard Specification for Crosslinked Polyethylene (PEX) Tubing

ASTM F877?- Standard Specification for Crosslinked Polyethylene (PEX) Hot- and Cold-Water Distribution Systems

WRAS regulations?- WRAS water supply regulations

Certificates:

NSF - refers to ASTM F876/877

WRAS- refers to regulations

ISO 9001:2015 – “Quality management system”

?

| TY | PEX Pipe |

| Roughness? | 0.0007 mm |

| Density | 0.926~0.959 g/cm3? ? ? |

| Modulus?of?elasticity | 600~800 MPa |

| Thermal?conductivity | 0.40~0.42?w/mK |

| Coefficient?of?thermal?expansion? ? ?? | 0.20 mm/mK |

ASTM

ISO

As per ISO 15875

?

| Size? ? ? ? ? ? ? ? | Length per coil (ft) | O.D. | I.D. |

| 3/8 | 300/500/1000 | 0.500''? ? ? ? ? ? ? | 0.350''? ? ? ? ? ? ? ? ? ? |

| 1/2 | 100/300/500/1000? ? ? ? ? ?? | 0.625'' | 0.475'' |

| 5/8 | 300/500/1000 | 0.750'' | 0.574'' |

| 3/4 | 100/300/500/1000 | 0.875'' | 0.671'' |

| 1 | 100/300/500 | 1.125'' | 0.682'' |

ISO

| Nominal size DN/OD? ? ? ? ? ? ? ? ? ? ? ? ? ?? | PIPE SERIES Wall Thickness |

|||

| ? | S6.3? ? ? ? ? ? ? ? ? ? ? | S5? ? ? ? ? ? ? ? ? ? | S4? ? ? ? ? ? ? ?? | S3.2? ? ? ? ? ? ? ? ? ? ? ?? |

| 12 | - | 1.3 | 1.4 | 1.7 |

| 16 | 1.3 | 1.5 | 1.8 | 2.2 |

| 20 | 1.5 | 1.9 | 2.3 | 2.8 |

| 25 | 1.9 | 2.3 | 2.8 | 3.5 |

| 32 | 2.4 | 2.9 | 3.6 | 4.4 |

| 40 | 3.0 | 3.7 | 4.5 | 5.5 |

| 50 | 3.7 | 4.6 | 5.6 | 6.9 |

| 63 | 4.7 | 5.8 | 7.1 | 8.6 |

As per ISO 15875

?

Working Performance:

Max. Working Pressure: 10bar(145 psi)

Cont. Working Temperature: 32°F (0°C) ~ 158°F (70°C)

Max. Instantaneous Working Temperature (Max. 10 min/day): 212°F (100°C)

Max Differential Pressure: 1 bar (14.5 psi)

Working Media:

1: Water

2: 50% water and 50% ethylene glycol

3: 50% water and 50% propylene glycol

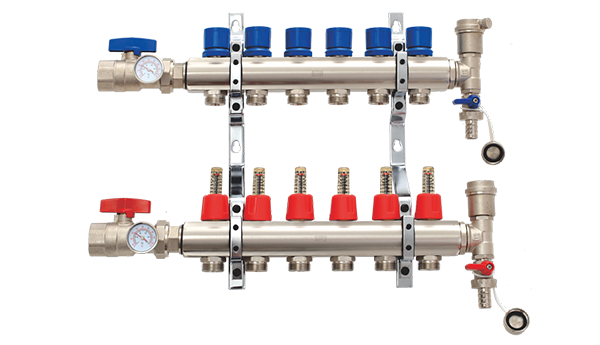

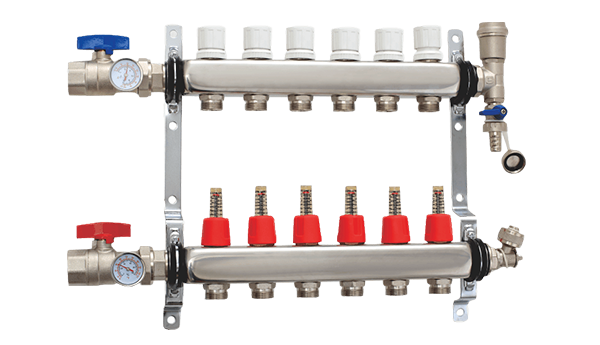

Material: ???????????????????????????????????????????????????????????????????????????????????????????????????????????????????

Manifolds Body: 304 Stainless Steel or brass

Port Connection: Nickel coated brass

Sealing Ring: EPDM

Flow:

Indication Scale - 0.5 ~ 5 L/min, Tolerance ±10%

Kvs - 1.10

?

Max. Working Pressure: 10bar(145 psi)

Cont. Working Temperature: 32°F (0°C) ~ 158°F (70°C)

Max. Instantaneous Working Temperature (Max. 10 min/day): 212°F (100°C)

Max Differential Pressure: 1 bar (14.5 psi)

Working Media:

1: Water

2: 50% water and 50% ethylene glycol

3: 50% water and 50% propylene glycol

Material: ???????????????????????????????????????????????????????????????????????????????????????????????????????????????????

Manifolds Body: 304 Stainless Steel or brass

Port Connection: Nickel coated brass

Sealing Ring: EPDM

Flow:

Indication Scale - 0.5 ~ 5 L/min, Tolerance ±10%

Kvs - 1.10

?